TECHNICAL DATA

Facts

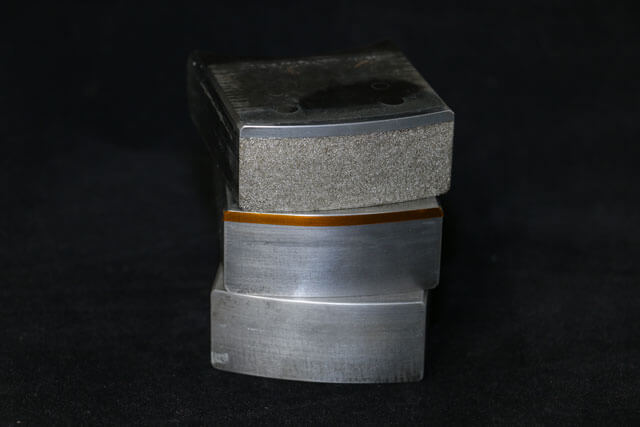

- Carbinite Metal Coatings offers customer-focused solutions for improving grip and reducing wear for a wide variety of applications in many different industries. It can be applied to worn-out dies, clamp blocks, and other fixtures to extend the life of your tooling.

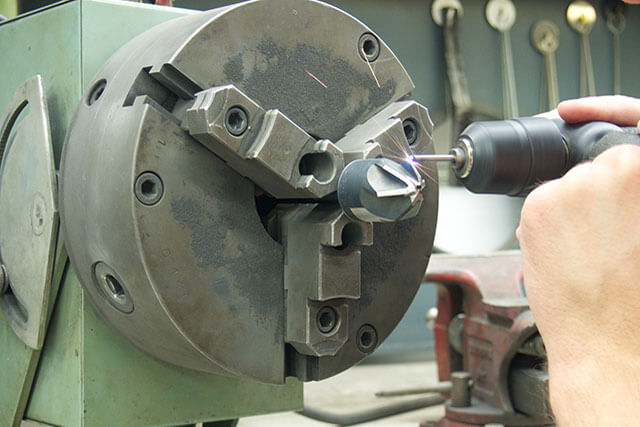

- Carbinite is not a spray process. Our carbide-based textured coating is applied using a process called Electro Spark Deposition (ESD), yielding a true metallurgical bond. This high bond strength far surpasses any spray-on coating currently available. Carbinite can be used as an alternative to thermal spray or diamond coatings in many applications.

- Carbinite can be applied to most metals that can conduct electricity. Our coatings really excel when applied to hardened A2 or D2 tool steel.

- Carbinite is guaranteed to not crack, chip, or peel and can be reapplied without additional build-up.

Specs

- Carbinite is primarily a high-friction coating. Carbinite increases the coefficient of friction of the base metal to which it is applied, benefitting applications where slippage is an issue.

- In applications needing an increase in the COF, Carbinite’s textured grades can be applied from 36 to 280 grit Emery equivalence.

- Where a smooth or sliding surface is required, Carbinite’s wear coating can be applied as smooth as Ra 2.5 μm or Ra 98.43 μin.

- Carbinite also hardens the base metal, taking some high-quality tool steels to over 70Rc.

- Carbinite can be applied to small areas and specialty parts of all shapes and sizes. We use special tape to mask areas for precision application.

- Automation is used for many high-quantity or large surface area applications.

Coating Materials

We offer:

- Five standard Emery equivalences that can be customized for your application.

- Tungsten-carbide for grades W thru 3.

- Stellite/carbide for grade 4, non-slip safety flooring, and dyno drums.