ROBOTIC GRIPPERS

The world of automation continues to grow by leaps and bounds as robotic technology becomes increasingly more sophisticated. You may use robotic technology in one or more areas of your workplace to improve safety, accelerate production, enhance quality, and ultimately increase profitability. A crucial element of any robotic cell is the end-of-arm tooling (EoAT) used to maximize the effectiveness of your automation cell. EoAT acts as the “hand” of the robot, with grippers of all shapes and sizes acting as the “fingers”. These components allow your robot to perform jobs such as repetitive pick-and-place actions, precise welding, complex assembly, and material/product transport.

- Vacuum grippers can be used to move delicate products.

- Pneumatic grippers shine in tight spaces.

- Hydraulic grippers excel in strength and force.

- Servo-electric grippers are easy to control.

Grippers and gripper fingers should be customized for your specific application. An experienced integrator can help you choose the right gripper (or combination of grippers) for your application. Sometimes even the most carefully planned robotic cell can experience slippage of raw materials, finished products, or packaging units from gripper fingers. When you experience slippage during your manufacturing process, this can cause employee injuries, damage to your end-product, and production delays. Some areas where you may need a better grip provided by a textured metal coating are:

- Packaging products in slippery bags, such as potato chips

- Packaging heavy products in large bags, such as pet food

- Transport using plastic pallets

- Hydraulic gripper fingers that are slippery from oil

- Bin sorting of assorted products

Application for Carbinite on Grippers and EoAT:

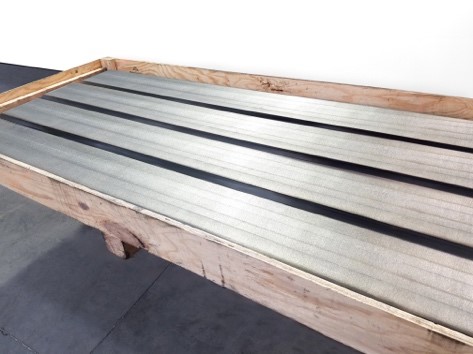

If you are experiencing slippage with your steel or aluminum gripper components, Carbinite can help. The application of Carbinite’s textured tungsten-carbide increases COF at least twofold. Carbinite is metallurgically bonded to your gripper’s base metal, creating a bond that is guaranteed to not crack, chip, or peel. The finer grades of Carbinite are useful when you need a better grip but want to avoid marking your end-product. Coarser grades work well in very slippery environments.

Some common gripper applications for Carbinite include:

- Loader jaws

- Gripper fingers of all shapes and sizes

- Robotic fingers

- Gripper pads

- Newspaper inserters

- Collator grippers

- Serrated grippers

- Material handling applications

Benefits of Carbinite’s Coating:

- Maximize the holding power of your gripper fingers

- Minimize raw material scrap

- Reduce damage to your end-products

- Improve employee safety

- Increase productivity

Carbinite strives to set the standard for metallurgically bonded textured metal coating. We specialize in serving all your industrial needs as our metal coating solutions are applicable to a variety of industries. These industries include metal coating for work-holding, metal coating for material handling, and many more.